Reconfigurable Gripper for Autonomous Warehouse Depalletizing

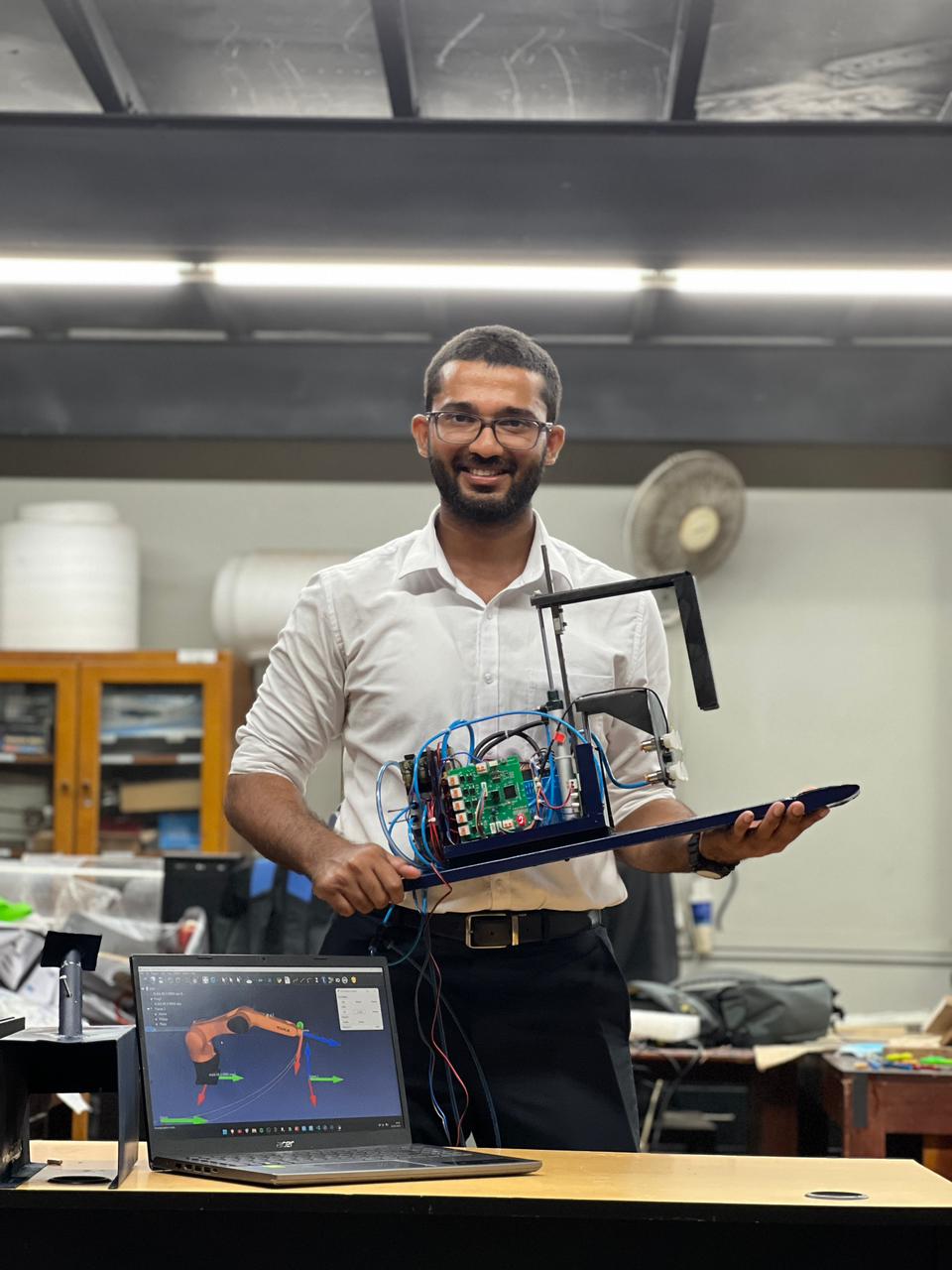

Robotic end effector with pneumatic actuation and ToF sensors for adaptive depalletizing, featuring microcontroller-controlled fork for real-time box handling in supermarket logistics.

Project Overview

Developed a reconfigurable robotic gripper designed for autonomous warehouse depalletizing tasks. The gripper utilizes pneumatic actuation and time-of-flight (ToF) sensors for precise box handling and manipulation.

The project involved extensive research into RF communication principles, protocol design, and implementation using microcontrollers and RF modules. The protocol includes features such as automatic repeat request (ARQ), forward error correction (FEC), and adaptive power control.

Testing was conducted in various environments to evaluate performance metrics including range, data rate, power consumption, and reliability. The protocol demonstrated superior performance compared to standard solutions in specific use cases.